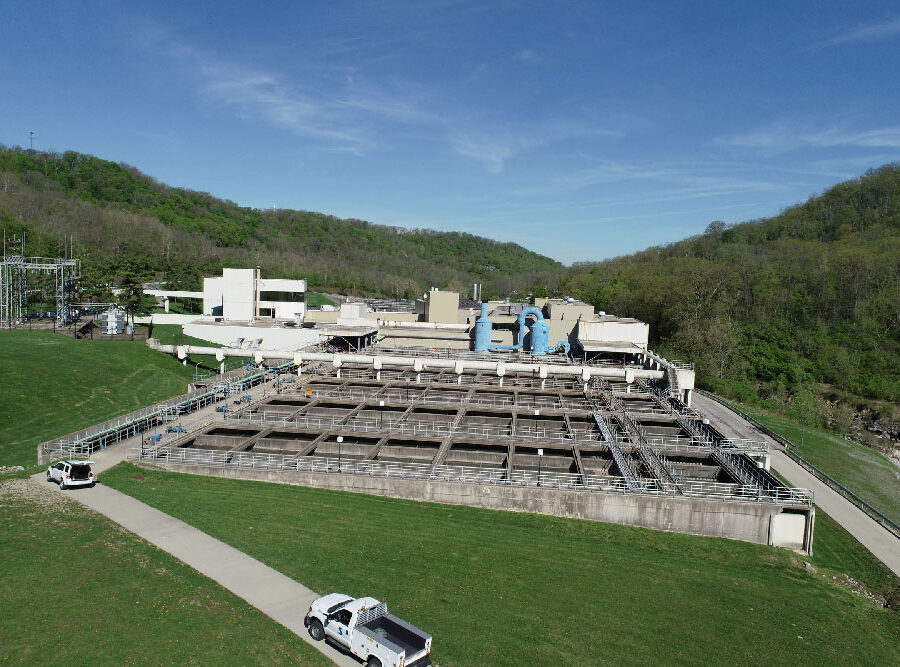

Dry Creek Water Reclamation Facility Headworks and Class A Biosolids Improvements

Project at a Glance

- Location: Madison, TN

- Client: Metro Water Services

- Partners: Brasfield & Gorrie

About the Project

The Dry Creek Water Reclamation Facility Headworks and Class A Biosolids Improvements Project represents a critical enhancement to the infrastructure supporting water treatment in Madison, Tennessee. Commissioned by Metro Water Services, this project focuses on modernizing and expanding key elements of the facility to ensure it meets current and future demands. By addressing both the physical and electrical components of the plant, the project aims to improve efficiency, reliability, and sustainability, marking a significant step forward in the region’s water management capabilities.

Scope of Work

The Dry Creek Water Reclamation Facility Headworks and Class A Biosolids Improvements Project represents a critical enhancement to the infrastructure supporting water treatment in Madison, Tennessee. Commissioned by Metro Water Services, this project focuses on modernizing and expanding key elements of the facility to ensure it meets current and future demands. By addressing both the physical and electrical components of the plant, the project aims to improve efficiency, reliability, and sustainability, marking a significant step forward in the region’s water management capabilities.

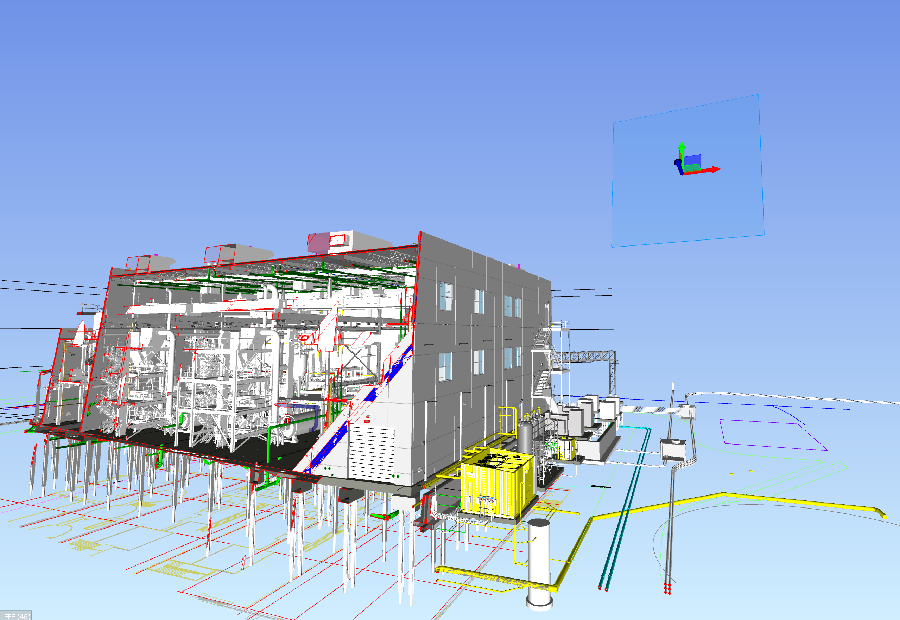

Headworks: A new two-story screenings and grit processing building was constructed, equipped with advanced screenings washer/compactors, grit dewatering, material handling, and load-out systems. This facility is designed to optimize the removal of debris and grit from the incoming wastewater, which is crucial for the overall efficiency of the treatment process.

Blower Building

The project involved significant upgrades to the existing plant electrical equipment housed within the Blower Building. This included replacing and modifying drive equipment for the existing blowers and updating motor control centers, ensuring reliable operation of the air supply necessary for the treatment process.

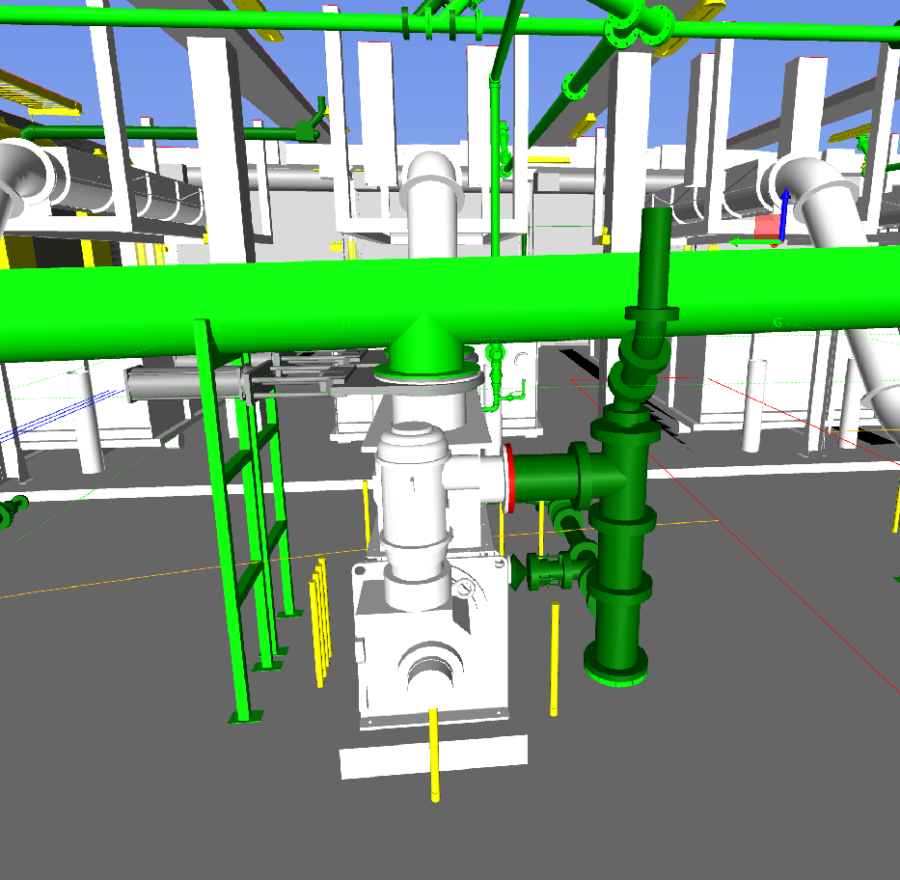

High Pressure Effluent System Improvements:

Electrical installations included a new switchboard designed to power a new High Pressure Effluent (HPE) pumping system, which plays a vital role in the final stage of water treatment before discharge.

Biosolids:

To enhance the processing of biosolids, a new three-story sludge drying facility was constructed. Electrical support was provided for the installation of systems critical to sludge management, including:

- Digested sludge feed wet well and centrifuge feed pump system.

- Dewatering centrifuges and dewatered sludge conveyor system.

- Polymer storage and feed system for centrifuges

- Centrate thickening system

Site Electrical Modifications:

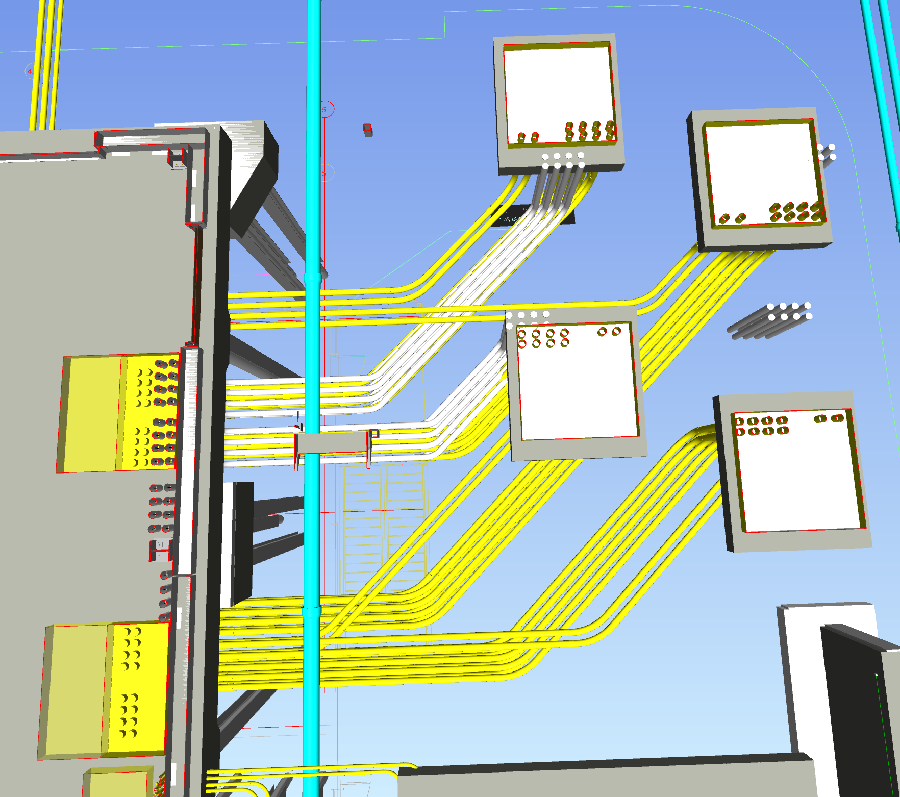

The project also encompassed extensive modifications to the existing site electrical distribution systems. This involved rerouting electrical ductbanks, upgrading unit substations, and modifying the electrical feed to the site from external utilities. A new electrical distribution system was installed to support the enhanced operations of the facility.

Challenges and Solutions:

The project faced several challenges, particularly in coordinating the electrical installations across multiple trades and managing the long lead times associated with equipment submittals and deliveries. To overcome these obstacles, the project team employed innovative Virtual Design and Construction (VDC) techniques. By closely collaborating with all stakeholders and meticulously coordinating the trades, the team ensured that the project stayed on track, despite the complexities involved.

Reflective Insights:

Our work on projects like the Dry Creek Water Reclamation Facility showcases our evolution beyond transportation and infrastructure. This project, a key enhancement to Madison’s water treatment infrastructure, underscores our expertise in modernizing critical facilities with cutting-edge electrical solutions. From advanced screenings and grit processing to sophisticated biosolids management and high-pressure effluent systems, Stansell Electric is at the forefront of driving efficiency and sustainability across diverse industries. We’re more than just an electrical contractor; we’re innovators committed to shaping the future of essential services and infrastructure.